3.6. Weather compensation and other controls

Weather compensation means automatically adjusting the heat pump flow temperature as the outside temperature varies.

This process is crucial to understand in practice, as it directly relates to the importance of design temperatures discussed so far.

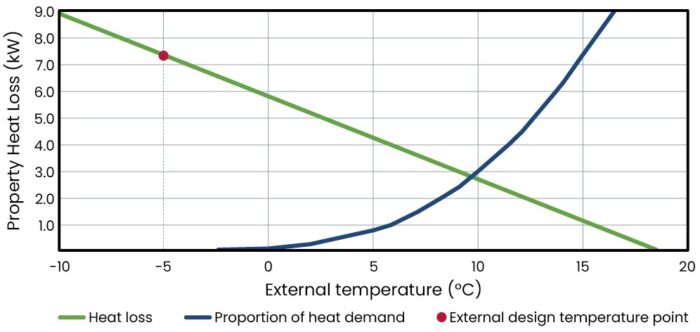

In our earlier heat loss calculation, we determined that 7.34kW of heat would be required to maintain internal temperatures when the outside temperature dropped to the DOT of -5°C. We then designed a system to meet this heat load using a flow temperature of 45°C through our heat emitters.

This ensures the system can operate effectively under these worst-case conditions. However, for most of the time the outside temperature will be higher, and the home will require less heat, as shown in this graph:

If the heat pump were to continue delivering heat at 45°C as the outside temperature got higher, the heat pump would have to cycle (turn on and off repeatedly) to maintain the right level of comfort. While this is not too much of a problem for a gas boiler, it will significantly reduce efficiency and product life for a heat pump. If the flow temperature were to reduce as the outside temperature increased, then the heat pump could continue to operate steadily and efficiently while delivering the reduced heat demand. The drop in flow temperature would also reduce the temperature difference between evaporator and condenser, further increasing the heat pump’s efficiency.

Weather compensation uses a sensor, either integrated into the air source heat pump outdoor unit or mounted on the outside of the building, normally on a north facing wall. The system uses this information to adjust the flow temperature, maintaining an equilibrium between the heat demand and the heat pump’s output. As well as increasing efficiency and extending system life, this also provides a more consistent level of heat compared to some boiler systems, which may constantly fluctuate from hotter to colder around the target temperature.

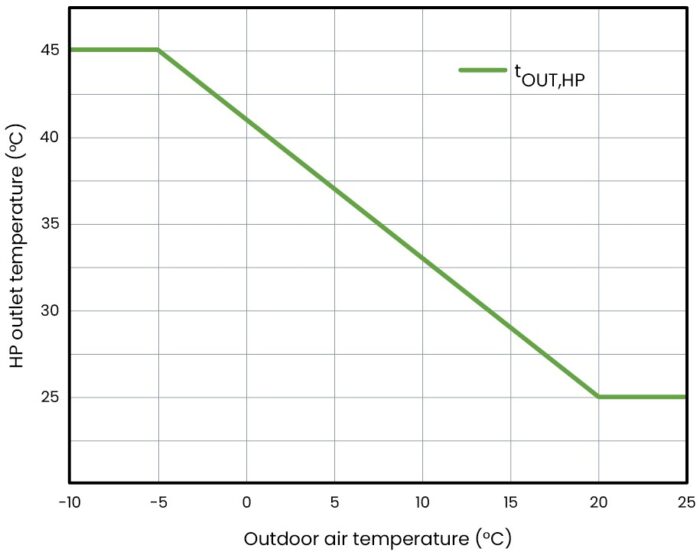

Some weather compensation systems use two flow temperature set points – a maximum and a minimum – and the system effectively draws a line between them as shown below:

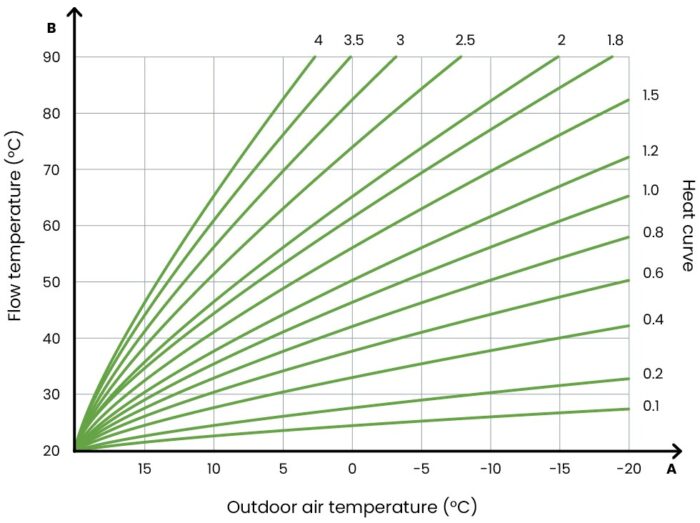

Other weather compensation systems use numbers to represent curves, and this will need to be chosen as part of the design, and form part of the information given to the team onsite. Some will allow for further customisation by adjusting the curve or drawing one in from scratch.

Using the manufacturer’s curves above, a curve of 1.0 would give us a flow temperature just over 50°C at a -5°C outdoor temperature and an expected comfort setpoint of 21°C. At the other end all the curves have a flow temperature of 20°C at 20°C outdoor temperature. Most houses will respond well to a minimum flow temperature of between 20°C and 25°C bearing in mind some manufacturers will have specific requirements.

Most heat pumps offer some form of easy adjustment to the curve, such as allowing an offset to be applied to a fixed curve. Any adjustments and their conditions should be discussed with the customer at the annual service.

Load compensation is similar to weather compensation, but the flow temperature is adjusted based on the internal temperature. Heat pumps always include weather compensation and so load compensation is an additional feature offered in some systems. The combined compensation approach is sometimes known as weather compensation with room influence.

Active weather compensation refers to any system that adjusts the weather compensation curve automatically to best meet the comfort requirements and minimise running costs by keeping the flow temperatures as low as possible.