3.4. Pipework insulation

It’s crucial to insulate all pipework outside of the thermal envelope of the building to avoid wasting valuable heat energy.

Investing extra time and effort in insulating the pipework will provide long lasting benefits for your customer. Maintenance of the insulation should be part of the annual service as insulation can become damaged and gaps may appear as materials settle after installation.

Any pipework external to the building should be insulated along its full length, apart from any anti-freeze valves, which may have specific instructions as mentioned previously. Care should be taken to fully understand the relevant instruction manuals and data sheets and the implications for insulating pipework with anti-freeze valves.

BS5422 (table 19) sets minimum insulation thicknesses for pipework, but all heat pump manufacturers set out their own requirements in installation manuals, and both requirements should be met. Often 19mm wall thickness UV stable class O insulation or equivalent will be specified, unless the external pipework exceeds 5m where greater wall thicknesses may be required.

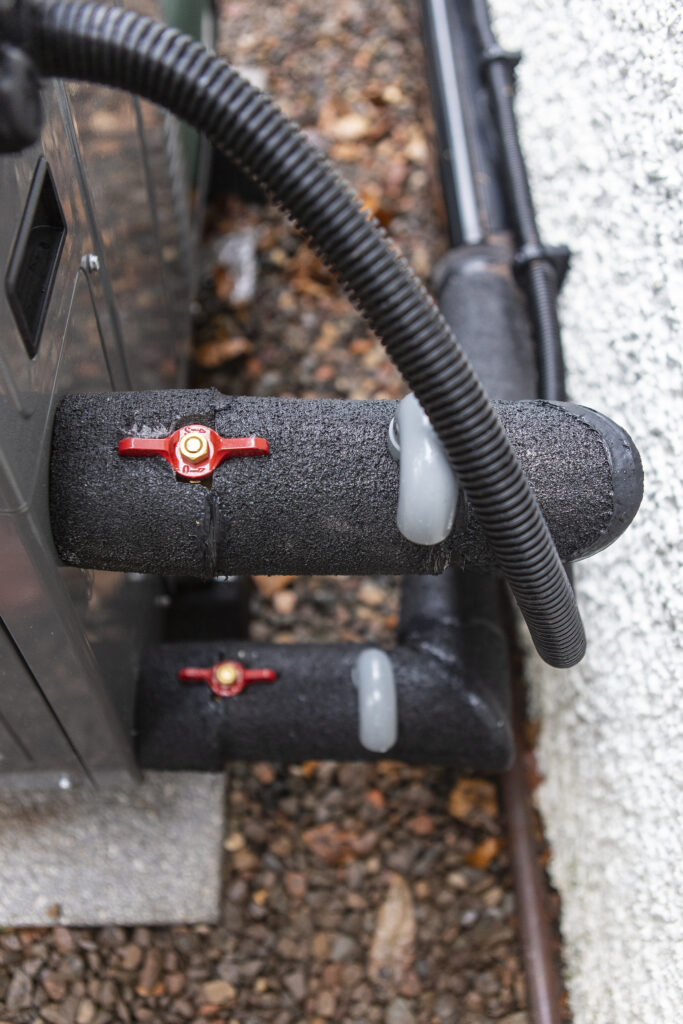

Gaps should be closed with either a sealant or purpose made tape. Pipe clips are available that will adequately support the pipework without interrupting the insulation.

Isolation valves and any gaps between the flexible pipes and the unit should be insulated. Handles can remain exposed and there are valves available with long shafts to allow for easy use with insulated pipework. These are particularly useful where thicker insulation (25mm or more) is required due to longer external pipework runs.

Pipework should be insulated where it passes through a wall or other entry into the building and suitably sleeved as per Building (Scotland) Regulations 2004.

Split systems

Most domestic heat pumps in Scotland are monobloc systems, with the evaporator and condenser in a single unit fitted outside the property. However, some installations may be split systems, with the evaporator outside the building and the condenser inside. Refrigerant is piped from the outside unit to the inside unit, rather than system water.

This refrigerant pipework needs to be insulated, just like the water/glycol pipework in a monobloc system, as it’s carrying just as much heat. A registered F-gas engineer is required to fit this pipework and charge the system.