2.1. Product standards and selection

What standards must insulation products meet?

There is a wide range of insulation materials, including those based on minerals, such as mineral wool, various types of foamed plastics, and natural products such as cellulose. They are available in various forms including rigid boards, batts, loose (injected), and quilts, depending on the intended application.

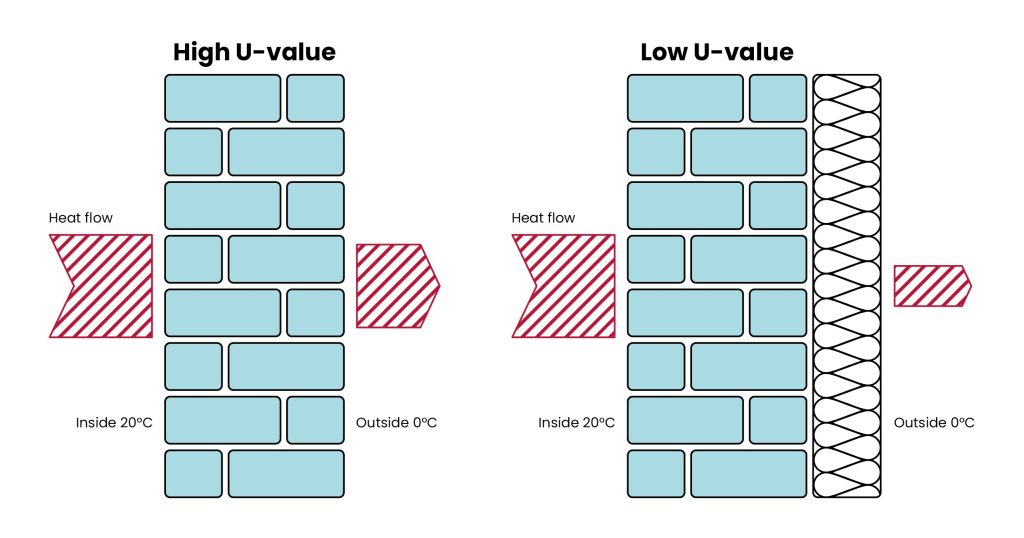

How effective a particular material is at reducing heat flow is described by its thermal conductivity, or K-value. This is also known as the lambda (λ) value. The lower the K-value, the better the performance of the insulation material. The R-value (or ‘resistance’) indicates how good a material is at resisting the flow of heat at a certain thickness. The higher the R-value the better.

The inverse of the sum of the R-value for each layer of a building element is used to calculate the overall U-value. Adding an additional layer to a building element increases the overall R-value and reduces the U-value of the finished structure thereby improving energy efficiency.

In practice, insulating materials can have various properties that affect their suitability for specific uses, such as:

- Tensile strength

- Thermal expansion/stability

- Reaction to fire

- Resistance to oils, liquids, gas fumes, acids, and alkalis

- Density/weight

- Impact resistance

- Vapour resistivity

- Resistance to moisture

You can typically find guidance on insulation products and their suitability for various applications, along with standard design details, from manufacturers or suppliers. The Scottish building regulations require that the materials used must be durable and fit for their intended purpose. The suitability of materials is demonstrated in various ways but is mostly assessed through:

- CE or UKCA marking demonstrates that the material is safe to place on the market and meets a Harmonised European Standard or has been subject to a European Technical Assessment. However, CE/UKCA marking alone does not necessarily indicate that a material is suitable for the intended work although the underlying standard may specify how the product should be installed in a particular application.

- Manufacturers Declarations of Performance which include more detailed information.

- Compliance with British Standards may indicate whether the material is suitable for the intended use.

- Independent Certification Schemes such as Agrément Certificates which assess a product’s performance and provide evidence that it is suitable for the intended application and can help satisfy the building regulations. They may also specify the scope of use and how the product should be installed.

In practice insulation is usually sold as a ‘product’ which would usually carry a CE or UKCA mark, or a proprietary ‘system’ comprising a range of specified components which meet a defined specification and are assessed as a whole under an independent certification scheme.

- An example of a product is loft quilt

- An example of a system is cavity wall insulation or external wall insulation (sometimes referred to as an ‘external thermal insulation composite system’)